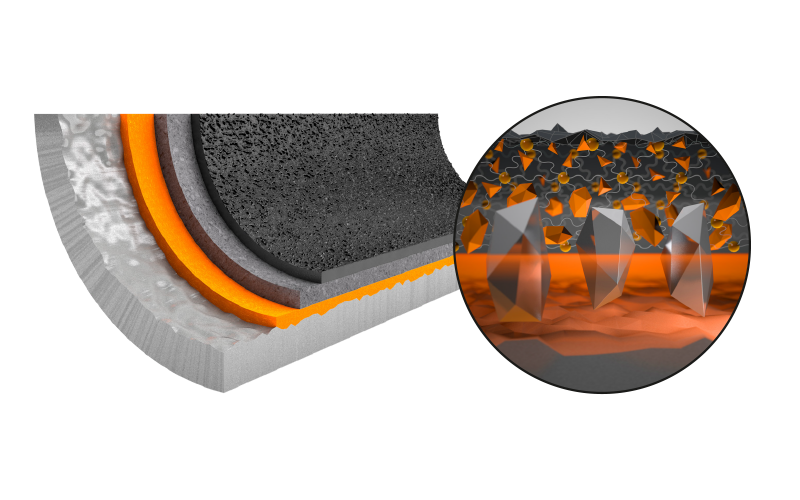

DURIT Professional R (PROFESSIONAL)

is a three-coat system based on an innovative multi-polymer combination specially developed by ILAG. This product is characterized by an outstanding scratch resistance. Due to its slightly rough and hard surface it is possible to use carrefully metal utensils to stir foodstuff in the cookware product.

1. TSurface sealing for highest abrasion and scratch resistance, as well very good non-stick effect

2. Very high reinforced mid coat for outstanding wear resistance

3. Ceramic reinforced primer with special NMP-free technology

4. Specially prepared substrate for an optimum adhesion of the coating to the cookware product