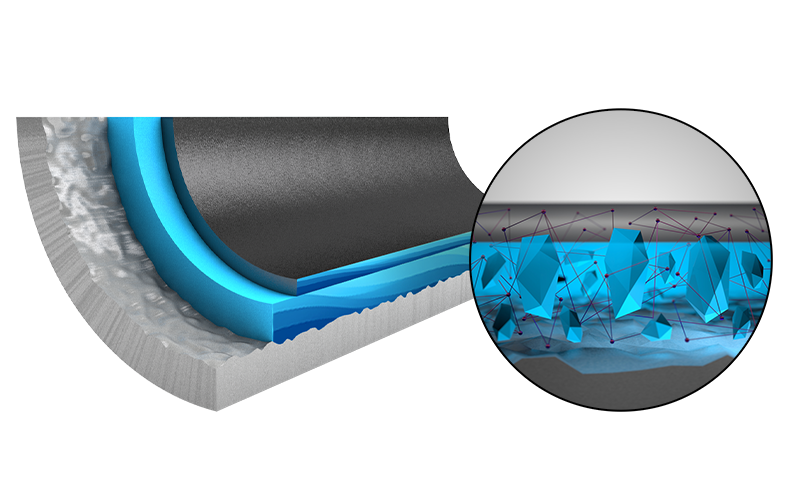

ILAFLON Resist SP-500 PFAS-free with Swiss Shield

is a two-layer, barrier-optimized non-stick system with that impresses with its very good performance.

1. Durable, corrosion-resistance non-stick surface for good scratch resistance

2. Barrier-optimized base coat for good durability

3. Specially prepared substrate for an optimum adhesion